Our Services

Embrace the future of manufacturing with our specialized services, dedicated to bringing your visions to life.

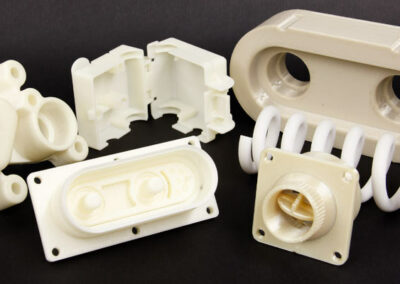

Custom Plastic Thermoformers & Vacuum Forming (including thermo-formed plastic packaging)

Our Custom Plastic Thermoforming and Vacuum Forming services deliver bespoke solutions, tailored to the unique requirements of every client.

With an emphasis on quality and precision, we also provide thermo-formed plastic packaging, ensuring that your products are both protected and presented in an appealing manner.

Design, Prototype & Production Specialists

Benefit from the efficiencies of using a full-service plastics manufacturer for your thermoform and assembly needs. Put fifty years of experience and skill on your side by giving the plastics experts at Faro Industries a call today.

CNC Machining

Silk Screening

Ultrasonic Welding

Painting

Hot Air Welding

Solvent Bonding

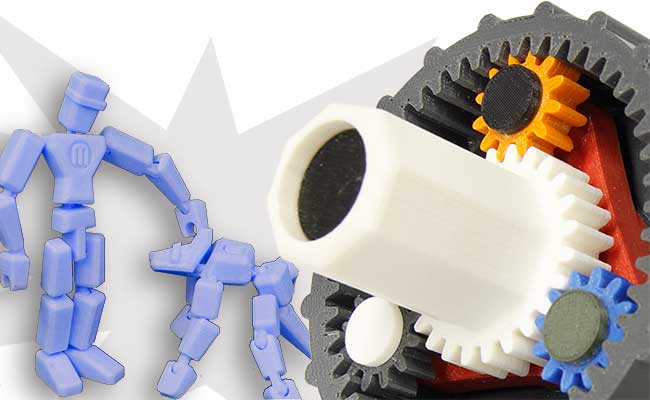

3D Printing

Harness the power of 3D printing with our state-of-the-art machines and skilled technicians.

From intricate designs to complex structures, we turn your digital blueprints into tangible prototypes, enabling faster design iterations and accurate design verification.

Prototypes, Models & Production

3D Printing

Harness the power of 3D printing with our state-of-the-art machines and skilled technicians.

From intricate designs to complex structures, we turn your digital blueprints into tangible prototypes, enabling faster design iterations and accurate design verification.

Prototypes, Models & Production

16″ x 14″ x 16″

Rapid Prototyping

RTV Molding

Architectural Models

Direct Manufacturing

Cast Polyurethanes

Low-Volume Production

Complex Models

FDM Thermoplastics

Large Parts

Jig & Fixtures

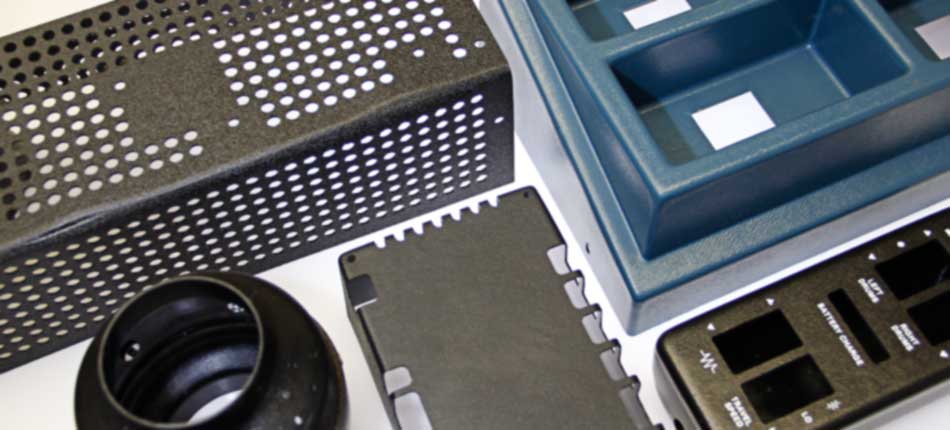

Machinists & Moldmaking

(CNC Machining)

With cutting-edge CNC Machining technology and a team of seasoned machinists, we transform your designs into tangible, high-quality molds.

Our molds are not just instruments; they are the heart of your product’s manufacturing, ensuring consistency and quality in every piece.

Facilities List

Equipped with the latest machinery and driven by a team of experts, our facilities list showcases our commitment to delivering unparalleled quality and precision in every project.

Facilities List

Equipped with the latest machinery and driven by a team of experts, our facilities list showcases our commitment to delivering unparalleled quality and precision in every project.

THERMOFORMING / VACUUM FORMING

-

- 3 INLINE MACHINES WITH A MAXIMUM MOLD SIZE OF 33″ x 33″

- 8 SINGLE STATION MACHINES WITH A MAXIMUM MOLD SIZE OF 46″ x 58″ AND A MAXIMUM DRAW OF 36″

- 1 THREE-STATION ROTARY MACHINE WITH A MAXIMUM MOLD SIZE OF 25″ x 35″

MACHINING / MOLDMAKING

-

- 3 CNC MACHINING CENTERS WITH A MAXIMUM TRAVEL OF 24″ x 50″ x 20 HIGH

- 7 CNC MILLING MACHINES WITH MAXIMUM TRAVEL OF 20″ x 50″ x 22″ HIGH

- 3 STANDARD VERTICAL MILLING MACHINES

MACHINING / MOLDMAKING

-

- 1 3D RAPID PRODUCTION SYSTEM – FDM (FUSED DEPOSITION MODELING) WHICH UTILIZES THREE DIFFERENT TYPES OF PLASTICS (ABS, POLYCARBONATE, AND ULTEM) AND HAS A MAXIMUM SIZE OF 16″ x 14″ x 16″ HIGH

DESIGN

-

- FULL DESIGN CAPABILITIES UTILIZING SOLID WORKS AND MASTER CAM

PAINTING

-

- FULLY EQUIPPED PAINT FACILITY WITH VENTED SPRAY BOOTH

QUALITY MONITORING & CONTROL

-

- COMPLETE QUALITY LAB WITH 3-AXIS CMM MACHINE

SECONDARY / VALUE ADDED

-

- KITTING AND REWORKS

- PUNCH PRESSES

- DRILL PRESSES

- LATHES

- OVERHEAD AND OVERARM ROUTERS, ROUTING TABLES

- PANEL SAWS, TABLE SAWS, AND BAND SAWS

- ULTRASONIC AND HOT AIR PLASTIC WELDERS

- JOINERS, PLANERS, SANDERS, SURFACE AND PEDESTAL GRINDERS

- HOT STAMPER AND RIVETER